2 minutes

AMB 1050 FME-W Probing

With small CNCs, the easiest way to adjust height (and sometimes the other axes) is to use a probe block. Generally, they’re just aluminum blocks of a known size that the CNC controller sends 5 volts through. Then you connect a ground clip to your spindle bit, and as soon as it touches the probe block the controller sees that electricity is flowing and knows that the tool is touching the probe block. If you know that your block is 15mm thick and sitting exactly on the top of your material, then it’s pretty easy to measure the top of your material to within some small fraction of a mm repeatably.

The annoying part is having to connect a ground clip to your tool every time. The Dewalt router that I used to use didn’t make life easy–as far as I could tell, no part of the router that didn’t spin had electrical continuity with the spindle, so there was no way to wire up the ground wire permanantly.

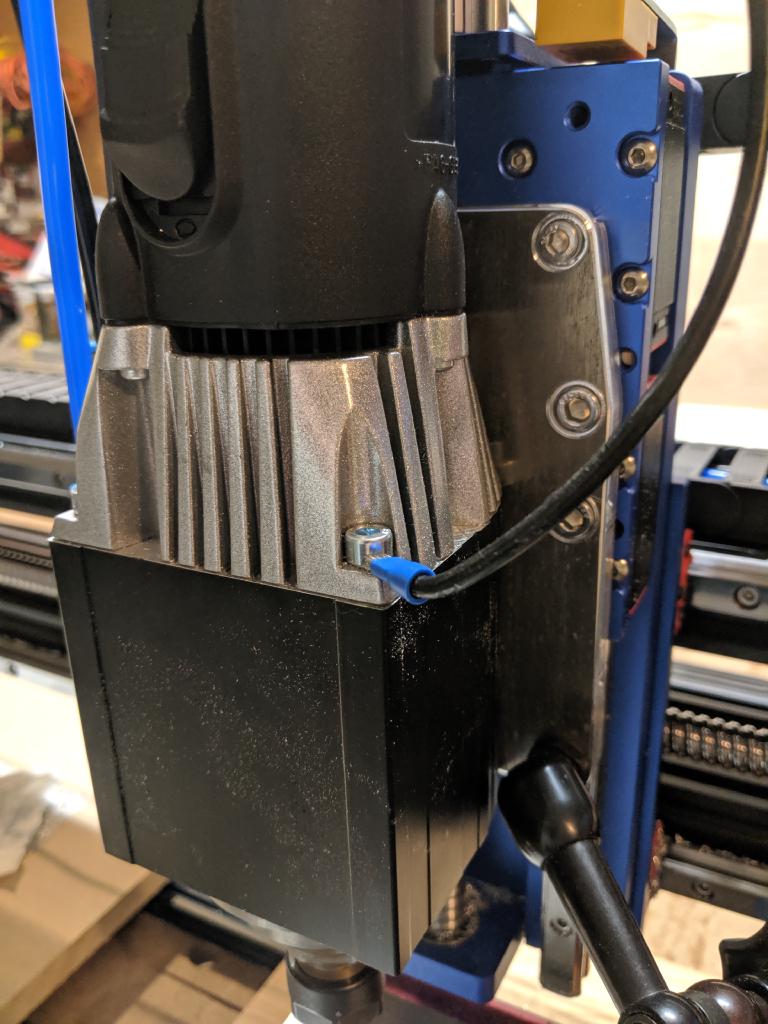

My new AMB spindle is much more useful in this regard. Its metal body is all connected to the spinning part of tool. I ended up running a ground wire through the drag chain and then crimped a connector onto it and screwed it right into the tool.

This makes probing really easy. I just set the probe block where I want it, get the tool within a few mm (but not touching), then hit the ‘probe’ button in CNCjs and wait a couple seconds.

Because it’s based on electrical conductivity, you can even be a bit clever. I realized that I’d screwed up on an aluminum part I was making and needed to re-run one operation after I’d removed it from the block that had held it in place. By that point, the corner that I was originally using as the X/Y origin had been completely milled away. I ended up telling Fusion 360 to use the center of one screw hole as the new X/Y origin for one last operation, and then lowered my bit down into that hole and ran a macro that probed X+/X-/Y+/Y- and then found the center. I was able to finish the last milling step, and everything was perfectly aligned.